Calibration Gas Mixtures

Calibration Gas Mixtures

What does Air Liquide offer?

- Unique portfolio of different gas mixture classes that allow a perfect match between the product performance and the application needs.

- The mixtures are characterized by the degree of accuracy, level of traceability, blend tolerance, process accuracy, analytical accuracy and other critical parameters.

- Leading-edge technology to produce highly accurate and stable gas mixtures containing component concentrations as low as parts-per-billion.

- Computerized and automated high-precision specialty gas filling system to achieve consistent, high-accuracy gas mixtures.

- Dedicated qualified team to perform startup, training and maintenance

- Specialty gas labs that are ISO 9001 registered and selected plants that are ISO/EC 17025 and 17034 accredited.

- Large network of laboratories, filling locations, service locations, regional specialty gas labs, equipment centres and research & development centres.

Different Gas Mixtures

Standard Mixtures

Air Liquide manufactures standard mixtures for various applications:

- Environmental Monitoring

- Appliance Testing

- Engine Emission Testing

- Oil & Gas Measurements

- Gas Detection

- Food & Pharma

- Research & Development

Custom Mixtures

Technical personnel will work with you to engineer your custom designed mixture to meet your exact application needs. A large selection and combination of components, concentrations, balance gases and container options are available for:

- Specialized customer requirements

- Developmental and exploratory mixtures

- Products with mixed blend and accuracy specifications, by component

- Liquid mixtures

- Convenient packaging

Accredited Mixtures

Provides confidence in the calibration decisions you make.

Specifies the general requirements for the competence to carry out tests and/or calibrations, including sampling. It is applicable to all organizations where testing and/or calibration forms part of inspection and product certification. ISO/IEC 17025 Accreditation is defined as a procedure by which an authoritative body gives formal recognition that a laboratory is competent to perform its work correctly and according to appropriate standards.

It’s the single most important metrology standard for test and measurement products. Nearly all national standards bodies and accreditation agencies around the world have adopted it. A growing number of companies require it and some industries have even incorporated it into sector-specific standards.

Air Liquide is committed to meet this international standard. Various manufacturing sites within the Air Liquide Group are now accredited as Calibration Laboratory.

- The quality and competence of the calibration mixtures sold by Air Liquide is now independently verified through the accreditation process, which eliminates the needs for supplier auditing and provides a greater confidence in your supplier decisions.

- Provide high confidence in the calibration decisions through validated uncertainty conformation. It directs Air Liquide calibration laboratories to:

- analyze the uncertainty of each measurement

- incorporate the uncertainty into the procedures

- provide the uncertainties with the calibration certificate and results.

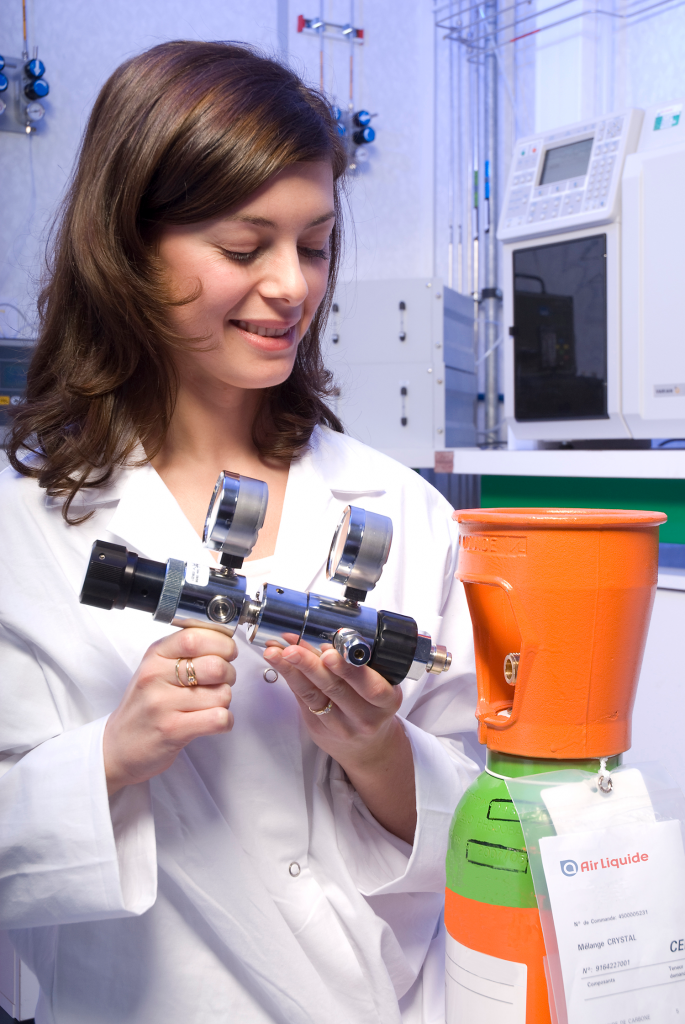

LABTOP™ advanced built-in regulator

Mixtures that feature an advanced built-in regulator will transform your calibration experience.

- Advanced built-in regulator

- Ergonomic and shock-absorbing cap

- New on/off hand wheel

- No more regulator stock, maintenance handled by Air Liquide

- Preset flow rate (upon request)

Refillable cylinders are available with LABTOP™ advanced built-in regulator to simplify your calibration and testing requirements.